• General practice is to use shallow foundations for the structures if the soil close to the ground surface possesses sufficient bearing capacity. However, where the topsoil is either loose or soft, the load from the superstructure has to be transferred to deeper firm strata. In such cases, pile or pier foundations are the obvious choice.

• There is also a third method which may in some cases prove more economical than a deep foundation. This third method comes under the heading ground improvement which is a technique that improves the engineering properties of the soil eg. shear strength, stiffness, and permeability.

Need for Engineering ground Improvement:

CONCERNS

|

| Shrinkage |

|

Collapsible soil

|

|

| Swelling |

|

Soft soil (Liquefiable soil)

|

|

Waste deposit

|

Alternatives to choose from:

• Abandon the site and locate the structure elsewhere

• Design deep foundation to transfer a load of superstructure to a strong stratum

• Redesign the structure according to the soil condition

• Adopt a suitable ground improvement technique to improve the soil quality

Ground improvement:

What is to be improved?

•To increase bearing capacity

•To reduce the amount of settlement

•To increase capacity to retard seepage

•To eliminate the possibility of liquification

•To increase the stability of the slope

Classification of Ground modification Techniques:

• Mechanical modification

• Hydraulic modification

• Physical and chemical modification

• Modification by inclusion and confinement

• Combination of above

Dynamic Compaction:

The mechanical properties of the soil are improved by transmitting high energy impacts to the soil.

- Invented by Louis Menard in 1969

- Most suitable for densification of loose granular soils

- Depth of influence or improvement is the depth where there are limited or practically insignificant amounts of improvement in the soil.

Vibroflotation:

BASIC PRINCIPLE

This technique involves densification of granular soil using a vibratory probe inserted into the ground

• It is a deep compaction technique

• It was invented in the mid-1930s in Germany

• It is successful in loose sandy soils typically with an original SPT value of 5 to 10

• Relative density of up to 85% can be achieved

Compaction Grouting:

BASIC PRINCIPLE

· It is a ground treatment technique that involves the injection of a thick consistency soil-cement grout under pressure into the soil mass, consolidating, and thereby increases the density of surrounding soils

· When injected into under-consolidated or poorly compacted soils, grout is able to push these materials aside compacting surrounding soil mass

Prefabricated Vertical Drains:

BASIC PRINCIPLE

- Saturated void space is reduced by rapid Drainage of water from it.

- Most suitable for soft clay

- After 90% consolidation has occurred the artificial surcharge is removed

Blast densification:

• BASIC PRINCIPLE: The principle of the method is to generate settlement of granular soil ground or fill by causing the soil to be compacted using the shock waves and vibration generated by blasting

• Nh = W1/3 /R ( 0.9 to .15 )

• ADVANTAGES: low cost, ease of treating large depths. The soil types treated by the explosive compaction method range from silt to gravel cobbles and boulders (cohesionless soils)

• Can treat up to a depth of 40m

• The method has not been widely accepted mainly because it is still based on experience rather than theory.

In-situ densification of sands

|

In-situ densification of sands

|

Grouting

• It’s the process of injecting a liquid solution or slurry into a soil or rock formation

• The material used is called grout

Types of grouts

• Suspensions (e.g. cement grout, soil-cement grout, bentonite grout)

• Emulsions (e.g. bituminous emulsion)

• Solutions (e.g. sodium silicate solutions, acrylic resins)

Desirable properties if grouts

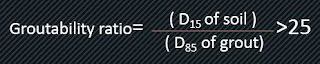

• Groutability

• Stability

• Setting time

• Permanence

• Toxicity

Generally used grout materials

|

Generally used grout materials

|

0 Comments